Service Telephone

+86-17773308230

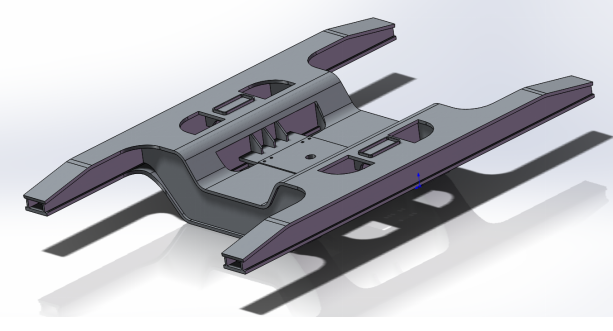

Three-axle Bogie

update time:2024/4/9 12:08:11

1. Overview

On February 15, 2016, our company was invited by Laiwu Iron and Steel Group Co., Ltd. to investigate the problem of easy damage to the bogie bearings of the 140T Iron Ladle Car. After on-site inspection and analysis, we found the following problems:

1.1 The bearings are tapered roller bearings, which are not suitable for line conditions with many small curves.

1.2 The longitudinal and transverse clearance of the axle box guide frame is insufficient, and the bearing is a non aligning roller bearing. Welding frame type bogies use the swinging of wheelsets to make the bogie pass through curves or turnouts. This requires a certain horizontal and vertical clearance between the axle box and the guide frame, and the axle box needs to swing. If the clearance is not enough, the wheelset bearings and axle box will bear additional lateral forces. This causes excessive force on the bearing, severe wear on the axle box, and easy damage to the bearing.

1.3 When the vehicle is under heavy load, the spring is basically compressed and there is no buffer for vertical load. This causes the bearing to be subjected to excessive impact force, causing damage to the bearing. In response to the above situation, on the basis of solving the above problems and not generating new derivative problems, we suggest the following renovation plan:

2. Description of Renovation Plan

2.1 Bearing Axle Box

Adopting self-aligning roller bearings, model 22332C/W33, with an inner diameter of 160mm and an outer diameter of 340mm, and a bearing width of 114mm. The bearing positioning method adopts the fixed method of inner and outer rings. Due to the change of bearings, the axle box needs to be made a new one. For specific dimensions, see the drawing (CYZ04-30-01-101) of the axle box.

2.2 Spring Set

In view of the fact that the spring is compressed under heavy load, it is necessary to replace the spring set. Properly adjust the spring wire diameter, middle diameter and stiffness to prevent it from being crushed to death under heavy load. Each set of springs consists of an inner spring and an outer spring. The inner and outer springs rotate in opposite directions. The outer spring is right-handed and the inner spring is left-handed. The total stiffness of the spring group is 1984N/mm, and the spring parameters are as follows:

(1)Outer Spring

Rotation Direction: right

Wire Diameter: Φ 45mm

Middle Diameter: Φ 180mm

Stiffness: 1517N/mm

Free Height: 341mm

(2)Inner Spring

Rotation Direction: left

Wire Diameter: Φ 25mm

Middle Diameter: Φ 100mm

Stiffness: 467N/mm

Free Height: 341mm

2.3 Framework and Guide Frame

Due to the changes in the middle diameter and free height of the spring, the original guide frame cannot be used. In order to ensure the clearance between the guide frame and the axle box, the position of the guide frame has been changed. Due to the different force distribution of the framework, both the framework and the guide frame need to be remade. Based on the original height of the center plate,spring stiffness and stress conditions, the framework has been redesigned. The framework adopts an H-shaped welded structure,which is mainly composed of side beams, cross beams, center plate beams, auxiliary beams, side bearing beams and other components. The plate is made of Q345 low alloy high-strength steel. The cover plates of side beams, cross beams, auxiliary beams, and side bearing beams are all made of 25mm thick plates, the web plates are made of 16mm thick plates, and the partitions are made of 12mm thick plates. The center plate beam is assembled and welded into a 100mm thick beam using a three-layer stacking method. The drawings refer to the Framework composition of CYZ04-20-00-000. Please refer to the report for the strength calculation of the framework.

3. Summary

Based on the redesign of the bearing axle box and the matching calculation of the spring, as well as the strength calculation and analysis of the framework,it is believed that all components of the three-axle bogie of Laiwu Iron and Steel Group Co., Ltd. 140T Iron Ladle Car, except for the wheels, need to be remade to achieve more reasonable operational performance and strength safety factor.