Service Telephone

+86-17773308230

10 kN Drop-testing Machine

update time:2024/2/20 11:07:43

10 kN Drop-testing Machine

1. Range of Application

The hammer dropping machine is suitable for drop-weight tests of 43 kg/m ~ 75 kg/m hot-rolling rails.

2. Main Technical Parameters

| Maximum drop-weight height | 5200mm |

| Hammer head lifting speed | 15m/min |

| Hammer weight | 1t |

| Winch rated pulling power | 10KN |

| Rope capacity | 100m |

| Rope speed | 30m/min |

| Power | 5.5kw |

| Rope diameter | 12mm |

| Maximum height of hammer dropping machine | 9802mm |

3. Main Structural Features and Characteristics

Hammer dropping machine mainly consists of the following parts: winch, hammer head composition, pier base, stand, its foundation, etc..

3.1

The winch model chooses standard winch.

3.2

Hammer head composition is connected by hammer head and hammer body with bolts, in which hammer head body is casted by ZG200-400 and hammer head uses 45 forged steel. The standard quality of hammer head is 1000 kg±5 kg, the circular arc radius in its bottom is 130 mm, and its hardness is 300 HBW ~ 350 HBW through heat treatment.

3.3

Pier base uses 45 forged steel with the circular arc radius of 200mm and the surface hardness of not less than 350 HBW. The center line spacing of two pier bases is 1000 +100mm.

3.4

The stand mainly consists of pillars, fences and leading sheaves, etc.. Pillars composition is mainly installed and welded by 320 U-steel, leading rail, connection plate and clapboard.

4. Hammer Dropping Machine Foundation Description

Hammer dropping machine foundation is divided into two kinds of schemes: concrete foundation and 10000 kg heavy anvil rigid foundation.

(1)Concrete foundation

Before installing hammer dropping machine, embed foundation bolts in concrete foundation when pouring coagulation after digging foundation, and install the hammer dropping machine columns and pier bases by foundation bolts connection;

(2)Anvil foundation

Anvil is the 10000kg heavy casting, the hammer dropping machine columns and pier bases are connected with anvil by bolts flexibly. Embed the anvil foundation within the foundation.

5. Working Principle

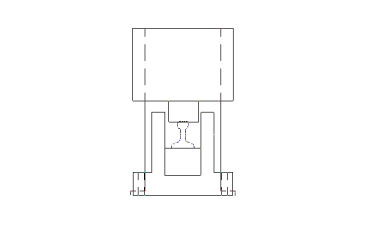

Its main purpose is to test the strength of the welded joint of rail, and the main working principle is: horizontally place the sample rail head upward on the two fixed rigid supports (pier bases) in the test stand, open the winch power switch to lift the hammer head composition by making the wire rope through the pulley block, and let the hammer head composition freely fall with its dead weight to blow the sample rail head, as shown in the figure:

Figure 1

6. Precautions of Operation and Maintenance

6.1 Pay attention to put the rail welded joint under the hammer head, and then lift the hammer head at a constant speed of 15m/min until the limit hook touches the baffle, which makes it separate from the limit hook to do free-fall motion, at this time, pause the wire rope movement of winch in time so as to make the wire rope terminal not run into the bottom of the connecting plate and destroy the entire transmission system, after the free-fall motion of the hammer head, make the limit hook return by controlling the winch wire rope through the pulley block, hooking the hammer head composition by artificial means to lift it, remove the rail, and then put into the other rail for repeated tests.

6.2 Before the entire test, coat the guide slot in the hammer head base with moderate melting grease in order to make the guiding smooth. In the process of repeated tests, the hammer head is likely to be destroyed due to the impact of the rail, it only needs to replace hammer head at this moment without the need to change the whole hammer head composition.

7. Working Position of Hammer Dropping Machine

The height from the hammer bottom surface to the rail surface is 3100mm at the first time, which is 5200mm at the second time.